From idea to solution: BUT students suggest how to improve logistics in warehouses

(Press release, Brno, March 11) Students of Industrial Design in Engineering at BUT are learning to design innovative solutions to selected problems. To create a successful product, they must consider the problem not only technically but also strategically and with a dose of creativity. This complex process is guided by mentors from Honeywell, a company collaborating with the university on education and selecting the problem to be solved. This year, they chose the topic of logistics automation in warehouses and distribution centers.

The traditional series of workshops for third-year Industrial Design in Engineering students at the Faculty of Mechanical Engineering at Brno University of Technology was held for the seventh time. The goal of the collaboration with Honeywell is to bring the academic world closer to the industrial sector and provide students with insight into real-world challenges faced by industrial companies.

"It is beneficial for students to observe how companies address the given topic. They get to experience how design intersects with technical, business, and financial feasibility. On the other hand, companies benefit from students challenging them, thinking outside the box, and coming up with unconventional ideas," explained Honeywell designer Tanguy Prevot.

Warehouse automation through students’ eyes

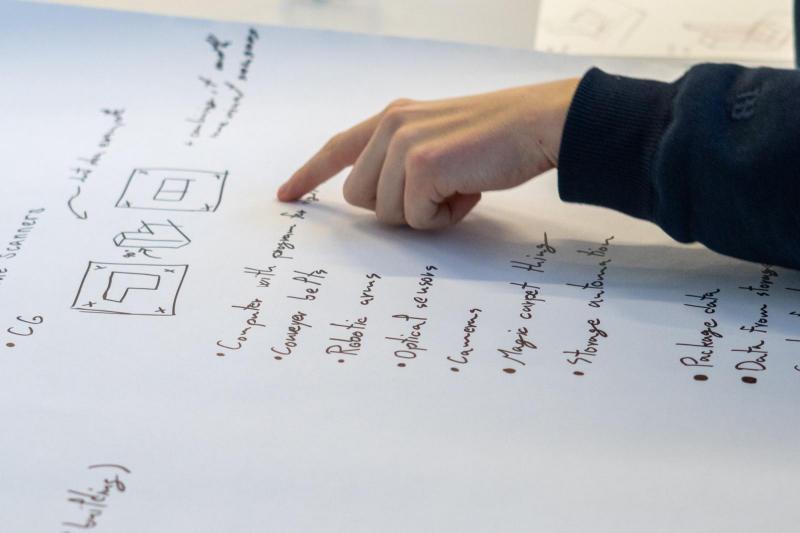

During the workshop, students work in small teams to simultaneously tackle multiple aspects of the selected topic and propose solutions for different sub-problems. This year, they divided their work according to the three main areas of warehouse operations: unloading pallets at the warehouse entrance, sorting packages, and loading vehicles at the warehouse exit. The students focused on making these processes faster, cheaper, and more efficient.

In addition to physical products, one group also designed a system-based solution. "Currently, loading in warehouses is typically handled by someone who picks up packages and places them into a vehicle’s storage space as they come to hand. We proposed thinking about the optimal arrangement of packages at the very beginning of the process. Our solution combines hardware and software elements, aiming to make loading as efficient as possible," described student Tadeáš Tobeš.

Throughout the academic year, the workshop includes two sessions, held in November and February. The first session is dedicated to understanding the problem and selecting specific aspects for the teams to focus on. In February, students continue their work, addressing functionality and proposing final solutions. These must not only fit into the overall system but also meet the requirements and expectations of the industry.

"The course concludes with final presentations, where the concepts are showcased and Honeywell evaluates the solutions to decide whether to continue developing them further," said Jan Vítek from the Department of Industrial Design at FME BUT. According to him, the most significant benefit of the collaboration is that students receive ongoing feedback from industry specialists.

Connecting education and industry

Strengthening the connection between education and practice is crucial for the future of technical fields. "Collaboration between R&D (Research and Development) companies and the support of STEM education through joint workshops allow students to apply theoretical knowledge to real-world problems, enhancing their skills and readiness for the job market. These partnerships also foster innovation, networking, and industry feedback, contributing to the development of a competitive and highly skilled workforce," said Tomáš Szaszi, Senior Director for Technology and Strategy in Research and Development at Honeywell.

By participating in the workshop, students gain valuable experience that benefits them during their studies and later in their careers. "I think the biggest lesson for students every year is that they shouldn’t come up with solutions too quickly. First, they need to understand what problem they are solving. I always ask them if there is a better way to achieve their goal," concluded Tanguy Prevot.

| Published | |

|---|---|

| Link | https://www.vut.cz/en/but/media/f19527/d283009 |

Responsibility: Mgr. Kamila Šmídková